I finally caved in and bought myself my first issue of Ottobre magazine as a treat, a few days before baby Button II arrived. I was so excited to unwrap it on the postnatal ward (although obvs not as excited as having baby himself). So many lovely designs to make for the boys!

The main reason to select this issue was the shirt (design 20):

|

| Shirt from Ottobre 1/2015, page preview pilfered from their site. |

The sizes start at toddler and go up to about age 12, as I recall, so I am hoping this pattern will see me through the next 10 years at least! Shirts are what I really like to make for Toddler Button, although I like the cool trousers in the image too, so he might be getting a pair of those. I just wanted to spare myself drafting shirt patterns constantly and focus on sewing them.

Anyway, the shirt has cuffs and a yoke, which I'd always wanted to add to my own patterns. Sadly, turns out that the yoke is stylistic only, and not double thickness in the original instructions (as it would be on normal menswear), but there is no reason why I could not cut it to be so. I'm also planning some yoke style changes to mix things up in the future, and maybe a re-draft of the cuff plackets, These are all speedy and minor drafting changes though, and should be fun.

I was quite nervous to cut into the fabric because I had some real concerns about the piece designs I'd found on the pattern sheets. Firstly, the left placket looked narrower than I was expecting, especially compared to the tiny schematic of it they print with the instructions. Secondly, I wasn't sure where to add seam allowances. They state "The patterns include hem allowances, placket extensions and placket facings. When cutting out the garment pieces, add seam allowances of approx 1cm ... to each edge of the pattern." Indeed, the placket patterns had marked seam allowances on them, but the front opening of the shirt didn't have allowances marked, so I wasn't sure if this was included under the placket rule or not.

The shirt front has two cutting lines marked "left" and "right" for the different sides. The right button placket is supposed to be narrow for style reasons, and the left placket has a more normal width. In order to have the collar stand fit the neckline correctly, once the plackets are inserted then the front pieces should finish along the line marked "left". Since I was super confused about how to get this to work, I ended up re-drafting a new pattern for a placket 2 x 44mm in width, adding the 1cm seam allowance at each edge. I cut two new plackets to my re-drafted design, cut both fronts down to the "right" line, then applied my plackets with a 1cm seam allowance. Both plackets are now identical, loosing a style feature, but at least the shirt has gone together. Reading back the instructions with hindsight, I can see how the left placket was supposed to work (and yes, you do need to add a seam allowance down the front), but I'm still confused about the right one. Perhaps all will be clear next time.

|

| You don't get good garment photos on this blog until I get spare time during the day with two hands! |

I made the 98cm size in our old friend the Laura Ashley soldier fabric. It's probably the last shirt I'll get out of it (boo hoo). I tried super hard to match patterns on this shirt, but there are still a few things I'd do differently with the pattern placement, especially now that I know how the front plackets work.

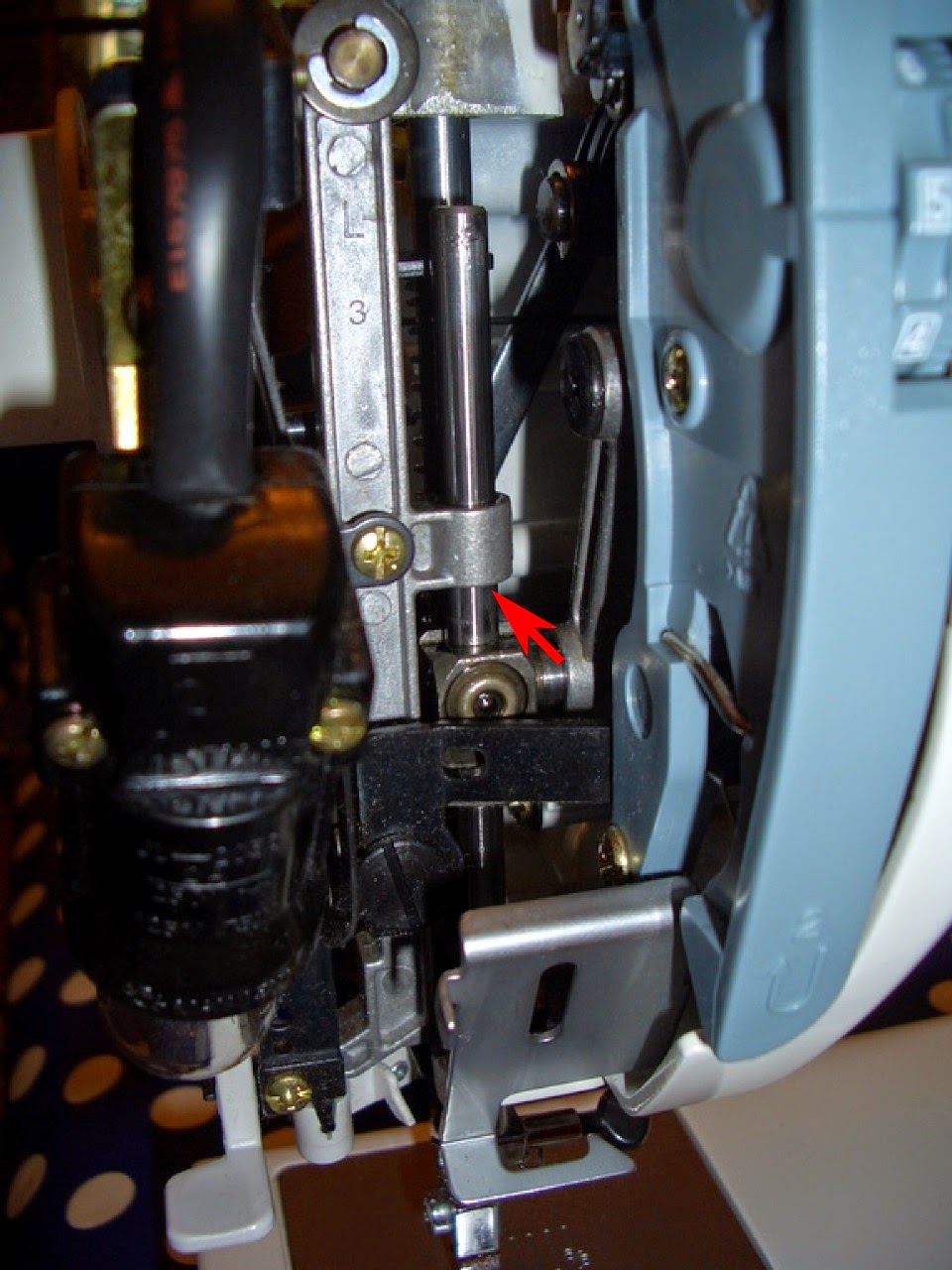

In other news, the cuff plackets were easier to figure out than I expected (I couldn't find their suggested method in a brief flick through this book so I did a trial run on scrap fabric). Also, the sleeves went in without fuss, and I overlocked and topstitched the armhole seam after clipping it, so it lay flat. Not sure why I never thought to clip the seam allowances at the armhole before (clearly I was being dense), so I'll chalk another one up to the learning experience. I'm still a bit rubbish at getting the hem done neatly and easily around the side curves. I wanted to do a rolled hem, but there was no way the thick plackets and seam allowances were going to feed through my rolled hem foot so I did a double turned hem instead.

|

| Check out that pattern matching! |

I'm really pleased with this pattern overall. I love the little details like the collar and pocket buttons, and I'm hoping the slim fit will look really smart on. I can't wait to make more of them! I massively underestimated the time it takes to sew it with two small children under 3. I'd quite forgotten how much work goes into a shirt with all the seam grading and top-stitching. However, the complexity is exactly why I love to make them; a t-shirt just wouldn't be so satisfying.

The shirt is for Toddler Button's little friend. It's my payment for the amazing Pocoyo birthday cake his kind and talented mother made for Toddler's birthday in December. I hope it fits him!

In other news, I am really disappointed with the range of shirting and printed dressmaking cottons available online. I want to make more funky and bold shirts for Toddler, but all the cotton poplin and lawn is turgid floral patterns that even I wouldn't wear. I'm going to have to resort to quilting cottons (argh) to make cool shirts. Toddler likes to wear shirts like Daddy, and he'd dress like a crayola box if I let him. (Favourite outfit: grass-green trousers, blue and purple t-shirt and bright yellow tank-top. Granny let him wear it once, because she is nice. Mummy is a big meany.)